Products

We craft acoustic solutions that bring added value to clients across the globe

Customized Acoustic Solutions

Tailor-made and Efficient Solutions

At HiAcoustic, we understand the importance of providing customized and efficient solutions for the acoustic conditioning of spaces housing generators and industrial equipment. We specialize in offering tailor-made solutions, employing the best products and materials available in the market.

How do they work?

Our team of engineers conducts a detailed evaluation, gathering the technical specifications of the room to be soundproofed. With this information, we design a customized acoustic solution and provide an accurate cost estimate. By considering crucial factors such as room dimensions, airflows required by the equipment, noise exhaust, and the presence of anti-vibration elements, we create solutions tailored to the specific needs of each client.

Acoustic Enclosures

A comprehensive solution for generator sets

HA-CA acoustic enclosures are specifically designed to specification to house internal combustion engines and, in particular, generator sets.

How do they work?

These enclosures are meticulously designed to confine and transport sound sources, in particular internal combustion engines and especially generator sets. Precise mass and stress calculations are carried out, taking into account structural safety and ensuring optimum acoustic and ventilation performance.

Tackling High Sound Levels

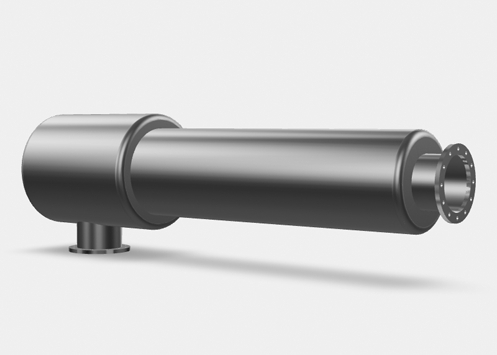

Tackling High Sound Levels

The HA-SE exhaust silencers are designed to reduce high sound levels, especially those produced by the exhaust gases of power generators, while also mitigating noise from compressors, pumps, turbocharged engines, and generators. They can attenuate sound by 30 dB or 40 dB, depending on the requirements.

How do they work? Exhaust gases enter the expansion-compression chamber; due to these volume changes, attenuation occurs at low frequencies. Subsequently, the absorption silencer is traversed for mid and high frequencies with an inner core.

Acoustic Cabins

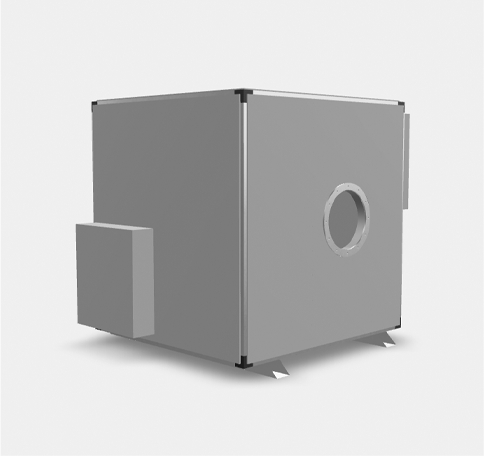

Integrated solutions for noise control

The HA/CA-80-DS Acoustic Cabins have been designed with the primary purpose of containing the noise generated by ventilation machines, preventing its spread in the surrounding environment. These cabins have various applications in industrial settings, providing an effective solution to protect workers, sensitive equipment, and reduce noise produced by compressors, fans, and other manufacturing equipment.

How do they work? Its operation is based on its ability to encapsulate and absorb the sound generated by ventilation machines. Its design is oriented to prevent noise from radiating outward, protecting both workers and delicate equipment. Below, key aspects related to the manufacturing, materials, and acoustic features of these devices will be detailed.

Rectangular Silences

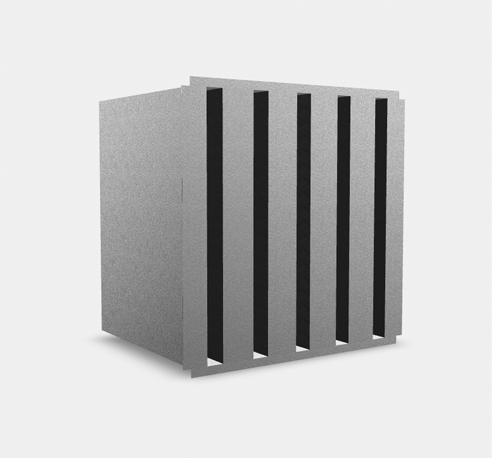

Designed for ventilation and air conditioning ducts

HA-R- /200 rectangular silencers are key components for noise control not only in ventilation and air conditioning ducts in generator sets, but also in heating and ventilation units, compressors and combustion engines.

How do they work? These silencers contain acoustic baffles made from inorganic, non-combustible fibres, strategically arranged to achieve specific levels of attenuation. Features such as an aerodynamic front (model A) minimise pressure drop and noise regeneration.

Acoustic Screens

High sound absorption capacity

The HA-PA Acoustic Screens represent an effective solution for attenuating noise radiated at the source by machines and equipment that require increased ventilation and cannot be encapsulated. This innovative approach allows maintaining an adequate ventilation level without compromising noise reduction. A noteworthy feature of these screens is their easy portability and the possibility of uninstalling them for later reinstalling in different locations.

How do they work?

Its on-site performance depends on various factors such as the size and geometry of the screen, the distance to the sound source, the proximity to the location where the screen effect is needed, as well as the presence of nearby partitions such as walls and ceilings. These elements work together to provide optimal acoustic control in industrial environments.

Acoustic Doors

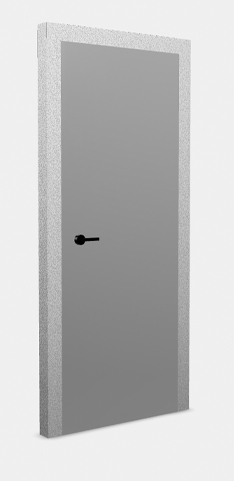

Outstanding for their versatility

The Acoustic Doors Model HA-PT/80, specifically designed for the industrial sector, provide effective isolation from machinery-generated noise. Proper installation plays a key role in ensuring optimal acoustic insulation performance. Let's explore their operation, manufacturing process, materials, and acoustic features.

How do they work?

The HA-PT/80 model ensures a perfect seal through plastic flanges, effectively reducing sound levels and enhancing acoustic insulation through the use of high-quality materials.